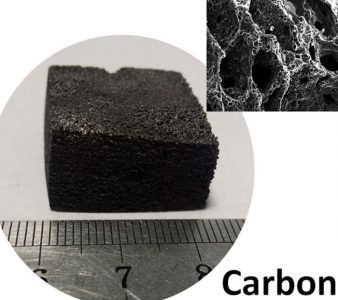

碳泡沫材料由于重量轻及高性能等特点,而成为了一种在航空航天领域极具前景的新绝缘材料。此前研究人员曾利用香蕉和西瓜等食物制备碳泡沫材料。 近日哈尔滨工业大学的研究人员却以烤焦的面包为材料制造出碳泡沫材料,同样具有隔热、电磁屏蔽等性能。

研究人员首先将面包放入烤箱烘干,并将温度设定在80℃(176°F),整个过程持续18小时。 随后面包被放入一个使用氩气的特殊熔炉中,将其煅烧成碳泡沫。 利用这种方法得到的碳泡沫材料与其他的碳泡沫具有相同的性能。 此外,这种碳泡沫材料比现有的材料阻燃性更好,成本也更低。

本文转自:CNBETA.com,仅供参考,原标题:哈工大利用烤焦的面包制成碳泡沫材料

小编补充参考文献:Multifunctional Stiff Carbon Foam Derived from Bread,Ye Yuan†, Yujie Ding†, Chunhui Wang†, Fan Xu†, Zaishan Lin†, Yuyang Qin†, Ying Li†, Minglong Yang†,Xiaodong He†, Qingyu Peng*†‡, and Yibin Li*† ,ACS Appl. Mater. Interfaces, 2016, 8 (26), pp 16852–16861.

The creation of stiff yet multifunctional three-dimensional porous carbon architecture at very low cost is still challenging. In this work, lightweight and stiff carbon foam (CF) with adjustable pore structure was prepared by using flour as the basic element via a simple fermentation and carbonization process. The compressive strength of CF exhibits a high value of 3.6 MPa whereas its density is 0.29 g/cm3 (compressive modulus can be 121 MPa). The electromagnetic interference (EMI) shielding effectiveness measurements (specific EMI shielding effectiveness can be 78.18 dB·cm3·g–1) indicate that CF can be used as lightweight, effective shielding material. Unlike ordinary foam structure materials, the low thermal conductivity (lowest is 0.06 W/m·K) with high resistance to fire makes CF a good candidate for commercial thermal insulation material. These results demonstrate a promising method to fabricate an economical, robust carbon material for applications in industry as well as topics regarding environmental protection and improvement of energy efficiency.