2016年元旦《Science》期刊为大家带来有关3D打印技术的重要进展消息:美国HRL实验室的科研人员实现了高分子陶瓷的3D打印,实现了3D制备高强度陶瓷产品。

尽管目前能被3D打印的材料在不断拓展,比如塑料、金属和玻璃,但是能用来3D打印制备高强度的材料仍然较少,特别是高分子3D打印材料在强度和耐热性能方面仍存在很大的局限性。虽然以往有研究陶瓷材料的3D打印,但是这样的工艺会造成材料中微小的缺陷,导致成品出现裂缝。

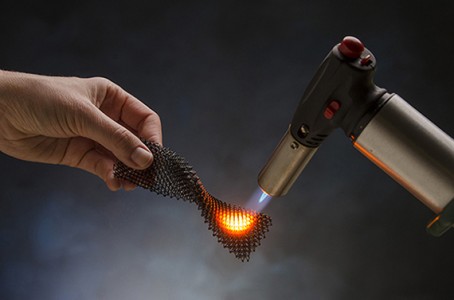

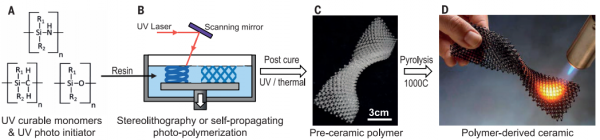

然而,HRL实验室科研人员换用了另外一种思路:先将可以转变成陶瓷的原料进行3D打印,后再进行处理转变为陶瓷产品。所以,HRL团队首先开发出一种可3D打印的陶瓷聚合物前体(原料,preceramic monomers),激光打印成型后再进行加热使之变成陶瓷,这项技术在原理上看似简单。

这种聚合物材料支持常见的激光3D打印技术,可以打印出复杂度更高的陶瓷物体,且速度则比传统的立体选择性激光打印快100到1000倍。更重要的是HRL发明的这种3D打印聚合物陶瓷强度高达当前商用泡沫陶瓷的10倍。

据了解,高强度耐高温陶瓷材料在航天工业有重要的用途,目前,航天器已大量采用陶瓷元件,例如机翼板和轨道火箭的内部结构。目前美国国防部高级研究计划局(DARPA)已经授予该团队烧蚀陶瓷外壳的开发合同,这种外壳用于航天器的隔热层,用于抵御返回大气层时产生的热量。据小编了解,开发技术的团队正寻求商业合作伙伴,如果您感兴趣,可以与他们联系,邮箱innovation@hrl.com,本文资料来源:HRL Laboratories。

小编认为这项技术未来将实实在在应用在工业中,技术参考文献:

Additive manufacturing of polymer-derived ceramics,Zak C. Eckel, Chaoyin Zhou, John H. Martin, Alan J. Jacobsen, William B. Carter, Tobias A. Schaedler,Science 1 January 2016: Vol. 351 no. 6268 pp. 58-62 ,DOI: 10.1126/science.aad2688

The extremely high melting point of many ceramics adds challenges to additive manufacturing as compared with metals and polymers. Because ceramics cannot be cast or machined easily, three-dimensional (3D) printing enables a big leap in geometrical flexibility. We report preceramic monomers that are cured with ultraviolet light in a stereolithography 3D printer or through a patterned mask, forming 3D polymer structures that can have complex shape and cellular architecture. These polymer structures can be pyrolyzed to a ceramic with uniform shrinkage and virtually no porosity. Silicon oxycarbide microlattice and honeycomb cellular materials fabricated with this approach exhibit higher strength than ceramic foams of similar density. Additive manufacturing of such materials is of interest for propulsion components, thermal protection systems, porous burners, microelectromechanical systems, and electronic device packaging.