这个标题很矛盾,既然热固性了,谈何热塑性。。

热固性材料的特点:化学交联,材料不具热塑性。

现在谈的问题的是,如何让热固性塑料具有热塑性,换言之,如何让交联的聚合物具有热塑性(加热一定温度下可流动成型)??

其中一种思路如下:

传统的热固性材料之所以不具有热塑性,本质原因在于化学结构的交联,束缚高分子链的运动。。所以如果,能让交联的聚合物在一定温度下(较高温度,比如加工温度)快速解交联变成非交联可塑性的材料,那么有可能实现交联聚合物的热塑性成型,而且,当温度降至室温是,成型后的材料会重新实现高分子链交联,回复至原来的交联聚合物(此时已经成型了的产品),保持交联聚合物的优良理化性质。

换言之,难点在于即找到这么一个交联反应,室温下可以自动实现聚合物链的交联并保持稳定,而在较高温度下,交联部分会解交联,使材料变成非交联材料从而具有可塑性,降温后,聚合物链又可以重新形成稳定交联结构。

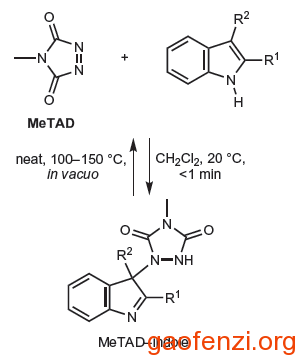

那么,这种交联反应存在吗?答案是肯定的,存在。如下图:

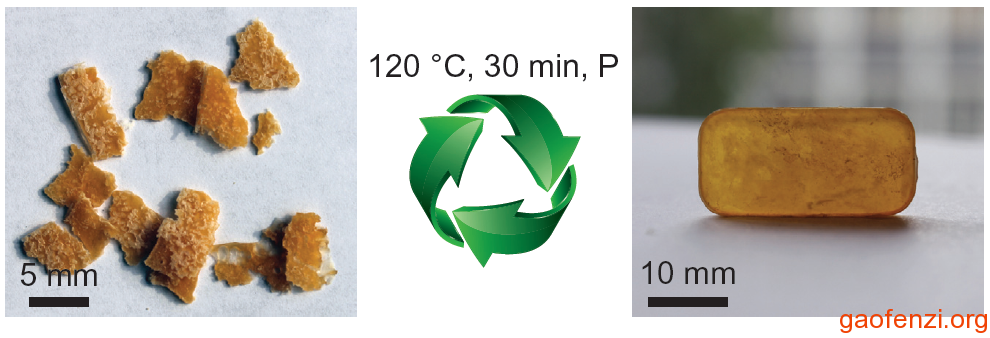

上图所示,左边为交联的聚氨酯PU材料碎片,经过加热至120摄氏度后,交联的PU变成非交联的PU,之后进行加工成型,冷却后,PU内部重新交联,得到右图形状产品。而且这种加工性能具有可重复性。

那么,这是一种神马交联反应呢?原理如下:

这个叫神马人名反应呢?笔者也不记得了,但是笔者知道这是点击反应(click chemistry)的其中一种类型。据悉,上述交联部分基团,可以方便地嫁接到聚氨酯原料单体中,以及甲基丙烯酸酯单体,所以对于热固性聚氨酯材料的研究具有重要意义。。你信吗?

详细情况,大伙可以参考文献:

Triazolinediones enable ultrafast and reversible click chemistry for the design of dynamic polymer systems

With its focus on synthetic reactions that are highly specific and reliable, ‘click’ chemistry has become a valuable tool for many scientific research areas and applications. Combining the modular, covalently bonded nature of click-chemistry linkages with an ability to reverse these linkages and reuse the constituent reactants in another click reaction, however, is a feature that is not found in most click reactions. Here we show that triazolinedione compounds can be used in click-chemistry applications. We present examples of simple and ultrafast macromolecular functionalization, polymer–polymer linking and polymer crosslinking under ambient conditions without the need for a catalyst. Moreover, when triazolinediones are combined with indole reaction partners, the reverse reaction can also be induced at elevated temperatures, and the triazolinedione reacted with a different reaction partner, reversibly or irreversibly dependent on its exact nature. We have used this ‘transclick’ reaction to introduce thermoreversible links into polyurethane and polymethacrylate materials, which allows dynamic polymer-network healing, reshaping and recycling.

Nature Chemistry 6, 815–821 (2014) doi:10.1038/nchem.2023

本文图片均来自上述文献。