每逢读到酱紫的材料研究都很兴奋,原理看似简约,但一般人都想不到。特推荐给大家,最好读一下参考文献原文。

据外媒报道,钛合金是我们打造过的最坚固的材料之一,但它们却有一个致命缺点,那是又贵又重。现在,来自马里兰大学的科研人员已经为钛合金找到了一个非常合适的替代品–“超级木”。通过一种全新的“致密化”技术,团队成功制造出拥有跟钢材一样强度和韧度的“超级木”。

虽然木头已经在多个领域找到用武之地,但马里兰大学的Liangbing Hu却为它的这份清单中加入了更多的名字。Hu及其领导的团队在过去几年研发出了多种新型木材用途,如比玻璃还硬的透明木材、利用木材燃烧净水、以木材和树叶为基础打造钠离子电池。现在,他们又带来了“超级木”。

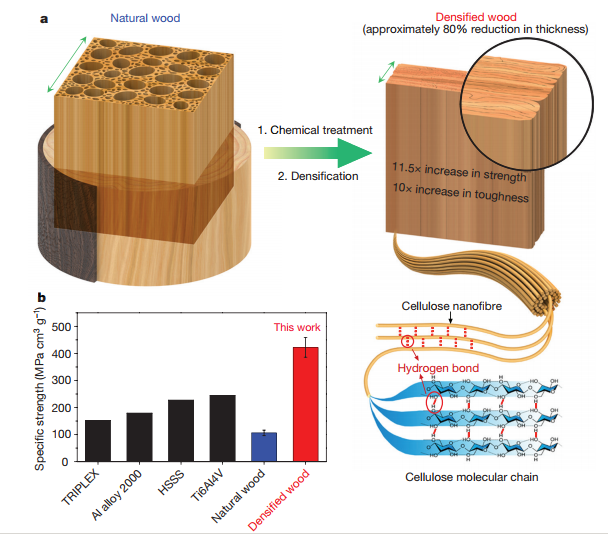

首先,团队需要在氢氧化钠和亚硫酸钠的混合水溶液下煮沸木材样本,这一步骤主要为了去除木材中的木质素和半纤维素;然后通过热压将处理过的木材的细胞壁压垮并形成规则排列的纤维素纳米纤维。最终得到的则是完全致密的木材,这要比天然木材要坚固得多。

Hu表示,通过这种方法处理过的木材的强度、韧性分别要比天然木材高出12倍、10倍。“这很有可能成为钢材甚至钛合金的有力竞争者,它真的非常坚固耐用。同时它又可以跟碳纤维相媲美,但价格却便宜得多。”

研究人员表示,这一技术可以应用到多种不同的木材,并且能一次性进行大量的处理。这将能为市场带来能够替代钢材乃至钛合金的更便宜、更轻的可再生材料。未来,它将能在汽车、飞机、建筑等任何使用到钢材的领域找到用武之地。这项研究报告已发表在《自然》杂志上。

以上编译内容转自:CNBETA,仅供参考学习。

参考文献:Processing bulk natural wood into a high-performance structural material,Nature volume 554, pages 224–228 (08 February 2018)

doi:10.1038/nature25476

Abstract

Synthetic structural materials with exceptional mechanical performance suffer from either large weight and adverse environmental impact (for example, steels and alloys) or complex manufacturing processes and thus high cost (for example, polymer-based and biomimetic composites)1,2,3,4,5,6,7,8. Natural wood is a low-cost and abundant material and has been used for millennia as a structural material for building and furniture construction9. However, the mechanical performance of natural wood (its strength and toughness) is unsatisfactory for many advanced engineering structures and applications. Pre-treatment with steam, heat, ammonia or cold rolling10,11,12,13,14,15,16,17,18,19,20,21 followed by densification has led to the enhanced mechanical performance of natural wood. However, the existing methods result in incomplete densification and lack dimensional stability, particularly in response to humid environments14, and wood treated in these ways can expand and weaken. Here we report a simple and effective strategy to transform bulk natural wood directly into a high-performance structural material with a more than tenfold increase in strength, toughness and ballistic resistance and with greater dimensional stability. Our two-step process involves the partial removal of lignin and hemicellulose from the natural wood via a boiling process in an aqueous mixture of NaOH and Na2SO3 followed by hot-pressing, leading to the total collapse of cell walls and the complete densification of the natural wood with highly aligned cellulose nanofibres. This strategy is shown to be universally effective for various species of wood. Our processed wood has a specific strength higher than that of most structural metals and alloys, making it a low-cost, high-performance, lightweight alternative.