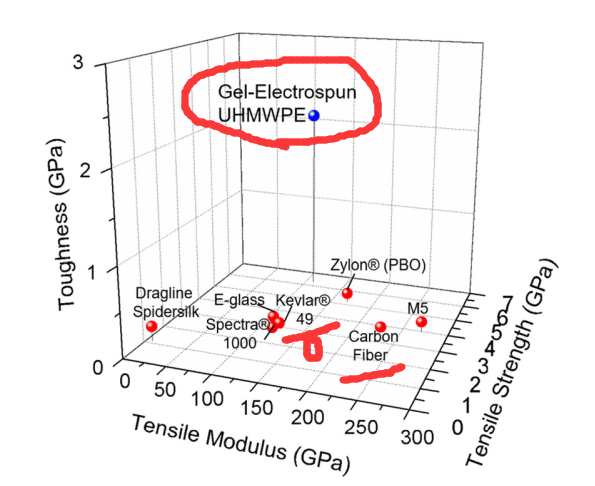

MIT研究人员通过凝胶电纺工艺获得超强又韧的超高分子量聚乙烯纳米纤维,力学性能超过凯夫拉。最大的特点是又强又韧,从下图中可以看出,其它很多超强材料强度和韧性不可兼顾。而且制备成本不高,可实现产业化,作为超强纤维,可预见其未来的应用前景。这么牛逼的材料可能是由于高结晶度、结晶取向和纤维内部缺陷少等综合因素造成。有兴趣的朋友请阅读参考文献。

不同直径超高分子量聚乙烯纤维力学与本体材料力学数据如下:

凝胶电纺示意图:

文献资料:Ultrafine high performance polyethylene fibers,

Abstract

Stiff, strong and tough ultrafine polyethylene fibers that rival the best high performance fibers, but with diameters less than one micron, are fabricated for the first time by “gel-electrospinning.” In this process, solution concentration and process temperatures are chosen to induce the formation of gel filaments “in flight,” which are subsequently drawn at high rates as a consequence of the whipping instability. The resulting submicron-diameter fibers exhibited Young’s moduli of 73 ± 13 GPa, yield strengths of 3.5 ± 0.6 GPa, and toughnesses of 1.8 ± 0.3 GPa, on average. Among the smallest fibers examined, one with a diameter of 490 ± 50 nm showed a Young’s modulus of 110 ± 16 GPa, ultimate tensile strength of 6.3 ± 0.9 GPa, and toughness of 2.1 ± 0.3 GPa, a combination of mechanical properties that is unparalleled among polymer fibers to date. The correlation of stiffness, strength and toughness with fiber diameter is attributed to high crystallinity and crystallite orientation, combined with fewer defects and enhanced chain slip associated with small diameter and high specific surface area. Gel-electrospinning improves the prospects for production of such fibers at scale.

阅读更多新材料信息,请加入我们的【新材料荟】社群阅读