最近关于石墨烯的进展还真不少,石墨烯汽车、石墨烯电池、某石墨烯概念股被特停。。

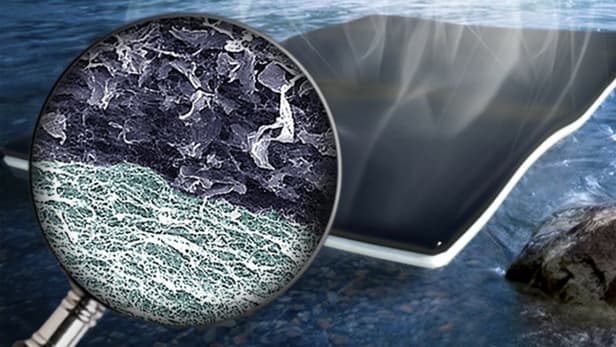

美国华盛顿大学(WUSTL)研究人员研发出一种基于石墨烯的生物泡沫材料,利用太阳能具备净化污水或淡化盐水的能力。这项技术非常适合于被大面积水悬浮颗粒物污染场地净化处理,而且成本并不高哦。这种材料采用了双层结构设计,其中底层由纯细菌纳米纤维素构成、上层为氧化石墨烯填充的细菌纳米纤维素材料构成,底层有点像海绵,底部纳米纤维层将水吸到上层,而上层氧化石墨烯吸收太阳能产生的热可以蒸发水分,于是留下各种悬浮颗粒或盐分,而水蒸气在顶部出来可凝结为纯水。研究人员表示,该材料非常轻、制造成本也比较低,可轻松实现大批量生产,使用时这种新型石墨烯生物泡沫材料可以直接铺在水体上,而无需水泵和管道。

尽管使用石墨烯材料来净水已经很是新奇了,但研究人员表示‘制造这种双层生物泡沫材料’的工艺才是实验中最创新的部分。他们在培养细菌纤维素时,在媒介中加入氧化石墨烯,之后它会被嵌入细菌产生的纤维素中,在某个阶段抽出氧化石墨烯,再引入新的媒介,后产生了下一层泡沫,其交接面的机械性能非常强大。这项研究已经发表在近日出版的Advanced Materials期刊上。Bilayered Biofoam for Highly Efficient Solar Steam Generation,DOI: 10.1002/adma.201601819,A novel bilayered hybrid biofoam composed of a bacterial nanocellulose (BNC) layer and a reduced graphene oxide (RGO)-filled BNC layer is introduced for highly efficient solar steam generation. The biofoam exhibits a solar thermal efficiency of ≈83% under simulated solar illumination (10 kW m–2). The fabrication method introduced here is highly scalable and cost-efficient.

以下是来自该校的报道:

Graphene oxide has been hailed as a veritable wonder material; when incorporated into nanocellulose foam, the lab-created substance is light, strong and flexible, conducting heat and electricity quickly and efficiently.

Now, a team of engineers at Washington University in St. Louis has found a way to use graphene oxide sheets to transform dirty water into drinking water, and it could be a global game-changer.

“We hope that for countries where there is ample sunlight, such as India, you’ll be able to take some dirty water, evaporate it using our material, and collect fresh water,” said Srikanth Singamaneni, associate professor of mechanical engineering and materials science at the School of Engineering & Applied Science.

The new approach combines bacteria-produced cellulose and graphene oxide to form a bi-layered biofoam. A paper detailing the research is available online in Advanced Materials.

“The process is extremely simple,” Singamaneni said. “The beauty is that the nanoscale cellulose fiber network produced by bacteria has excellent ability move the water from the bulk to the evaporative surface while minimizing the heat coming down, and the entire thing is produced in one shot.

“The design of the material is novel here,” Singamaneni said. “You have a bi-layered structure with light-absorbing graphene oxide filled nanocellulose at the top and pristine nanocellulose at the bottom. When you suspend this entire thing on water, the water is actually able to reach the top surface where evaporation happens.

“Light radiates on top of it, and it converts into heat because of the graphene oxide — but the heat dissipation to the bulk water underneath is minimized by the pristine nanocellulose layer. You don’t want to waste the heat; you want to confine the heat to the top layer where the evaporation is actually happening.”

The cellulose at the bottom of the bi-layered biofoam acts as a sponge, drawing water up to the graphene oxide where rapid evaporation occurs. The resulting fresh water can easily be collected from the top of the sheet.

The process in which the bi-layered biofoam is actually formed is also novel. In the same way an oyster makes a pearl, the bacteria forms layers of nanocellulose fibers in which the graphene oxide flakes get embedded.

“While we are culturing the bacteria for the cellulose, we added the graphene oxide flakes into the medium itself,” said Qisheng Jiang, lead author of the paper and a graduate student in the Singamaneni lab.

“The graphene oxide becomes embedded as the bacteria produces the cellulose. At a certain point along the process, we stop, remove the medium with the graphene oxide and reintroduce fresh medium. That produces the next layer of our foam. The interface is very strong; mechanically, it is quite robust.”

The new biofoam is also extremely light and inexpensive to make, making it a viable tool for water purification and desalination.

“Cellulose can be produced on a massive scale,” Singamaneni said, “and graphene oxide is extremely cheap — people can produce tons, truly tons, of it. Both materials going into this are highly scalable. So one can imagine making huge sheets of the biofoam.”

“The properties of this foam material that we synthesized has characteristics that enhances solar energy harvesting. Thus, it is more effective in cleaning up water,” said Pratim Biswas, the Lucy and Stanley Lopata Professor and chair of the Department of Energy, Environmental and Chemical Engineering.

“The synthesis process also allows addition of other nanostructured materials to the foam that will increase the rate of destruction of the bacteria and other contaminants, and make it safe to drink. We will also explore other applications for these novel structures.”

Singamaneni may be reached for interviews at singamaneni@wustl.edu; Biswas at pbiswas@wustl.edu.

From:https://source.wustl.edu/2016/07/dirty-to-drinkable/

微信回复“石墨烯”可阅读更多精彩内容哦。