首届欧洲塑料创新奖(The first European Plastics Innovations Awards)在近期的欧洲塑料协会年会上揭晓最终得主。此奖项一共被分成了7个大类,以鼓励在不同细分行业做出卓越贡献、富含创新精神的企业。

在年会上,欧洲塑料协会会长Partick Thomas与CEO Covestro表示:“欧洲塑料行业的发展很大程度上依赖于技术的革新与产品创新。塑料行业占据了整个工业体系中1/25的专利数量,这表明了塑料在现今的尖端技术领域的确保有一席之地。如果我们想要解决现阶段欧洲塑料行业所面临的问题,重中之重或许是对“创新”这一概念加大投入的力度。”

DG研发与创新机构的环境影响与资源效率部门负责人Kurt Vandenberghe说:“塑料行业的发展不能沿袭之前的老路子。”例如经济下滑、产能问题对行业的影响也被他归因为“缺乏稳定的塑料垃圾管理方案”。Kurt先生表示:“行业的发展遇到了瓶颈,我们必须通过创新这唯一的手段来让我们摆脱现阶段的困境。仅仅靠规范可能并不足以应付现今的问题,针对塑料行业的创新能力我们应想方法加以促进,而不是放任塑料行业本身成为矛盾之一。”

美国石油工程师协会CEO Willem De Vos表示:“我们一共考虑了37项塑料行业创新提案,其中各个都非常有吸引力。在经过深思熟虑之后,我们选出了其中七项作为本次的冠军,又从其余的提案中选出五项作为亚军。值得一提的是,所有的37项提案均是公司间合作的产物,而不是单独一家公司所作出的创新产品。”评审人员全都由行业内的学术精英组成,主要来自欧洲的各大高校与行业高端从业者。下一届欧洲塑料行业创新奖将在2017年年中揭晓,所有备选项目的申报截止日期为2016年年底。以下是此次获奖的七项创新项目:

最佳塑料设计奖:

颁发给DSM工程塑料公司专用Salomon牌登山鞋鞋底所设计的产品。原料基于DSM 生物基聚酰胺EcoPaXX。DSM公司使用复杂的设计,在原有材料属性上保持了产品必要的灵活性和刚性,也增强了它在低温、山地环境下的表现(降低水分吸收)。此聚酰胺材料非常适合注塑生产,也因为其从制备到生产都不会产生温室气体而获得殊荣。

This award recognises a company which has utilised any novelty in plastics technology to achieve a part with a design.

EcoPaXX has enabled Salomon to produce a chassis with an intricate design that is light, has the necessary mix of flexibility and rigidity, retains its properties at very low temperatures typical of mountain environments, and has reduced moisture uptake, despite being a polyamide.

The material is very suitable for injection molding and is certified as carbon neutral from cradle to gate. It is being used in the chassis of three models of Salomon’s new X Alp range of mountaineering shoes.

最佳最终处理设计奖:

颁发给Top Clean包装公司,其红酒、香槟的包装经过特殊设计,使得酒瓶在运输过程中一直受到保护。此外,包装材料在可行条件下极端轻质化,这将会降低其在使用并废弃后对环境的影响。此材料可以二次利用,并用以加工其他塑料产品。从设计上来看,此包装结构满足了干净、易于打开且节约空间的特性。

This award recognises a company which has produced a new product, which has taken into consideration the end-of-life

The wine/champagne pack allows handling/transport of the packed product and provides protection during transportation and falls. Replaces current bulky package and reduces environmental impact. Moreover, the wine/champagne pack can be reused in a second life as a shelving system for bottles (wine cellar)

Innovation in 3 points:

– Packaging that is clean and easy to open

– Nestable package for minimum storage space

– No particles or dust contamination generated by the packaging

优秀材料创新奖:

颁发给Evonik工业公司,其研发的VESTAMID NRG在全塑料管具中可以承受高压。在几十年的使用周期后,钢材被人们认作为最适合用于生产中等压力水管的材料。而在2012年,塑料产品第一次取代钢材,成为了高压管具的生产原料。Evonik公司在此项目上突入了超过10年的研发精力,并最终成功的设计出了可以完美取代钢材,用作城市管道系统原料的塑料材料。据悉,此类型材料已经可以进行量产。

This award recognises a company, which has created a product in any plastic technology by using new material (polymer), new material blends and/or new additives/fillers, allowing such product to be made.

For many decades steel was the only material for gas pipes in the medium‐pressure range. In 2012, however, it became commercially possible for the first time to replace steel by polyamide 12. Evonik worked on this development for more than 10 years.

The cornerstones of this achievement are the identification of the application, its technical realisation (from development of the polymer and compound to installation in the field), the committee work required and, not least, the effort involved in convincing pipe manufacturers and gas distribution operators of the advantages of the new material.

优秀复合产品奖:

颁发给DuPont公司,其研发的材料可以满足海洋中的使用,适用于离岸数据采集器、导航浮标、养鱼场笼子、饲料驳船,并满足海洋潮汐能以及其他发电设备的强度要求。而Tfi海洋聚合物基础材料可以用于控制混合聚合物中的分子运动,减少70%的分子间作用力,使其结构更为稳定。而与热塑性塑料弹簧机橡胶弹性体配合使用时,可以极大的减少海洋浮标的成本,并减少人为因素对海洋生态环境的破坏。

This award recognises a company, which has created a new product or a part that combines different materials (plastic and other) as to achieve new properties or new applications. This part may be produced through any plastic or other technologies, but must contain at least 20% polymer weight.

Offshore data & navigation buoys, marinas/pontoon; fish farm cages & feed barges, renewable energy-wave, floating wind and tidal platforms.

The Tfi Marine polymer base solution incorporates hybrid polymer mooring components to control the motion, substantially reduces forces by up to 70% and delivers better location holdings.

Consisting of a thermoplastics spring coupled with a rubber elastomer, it has the potential to substantially reduce mooring costs for buoys, aquaculture and ocean energy.

The taut keg design also reduces the sea bed damage from conventional mooring chains movement on the sea bed.

优秀可持续产品奖:

颁发给陶氏化学,其灵活的PacXPERT包装技术在塑料瓶包装中的应用,使得在介质为固体或粘稠产品时候可以重新盖紧并加以封装,常用在油桶或油罐中。使用塑料软包装来代替传统的刚性硬包装,生产的塑料桶、罐产品的容积范围在2升至20升之间。这种耐用、重量轻、灵活的结构有很强的适用性。使用这种轻质化的优秀包装材料可以在很大程度上降低运输成本并减少二氧化碳等温室气体的排放。

This award recognises a company, which has created a product with improved sustainability in

any plastic technology replacing a product, which formerly was made out of other materials.

Flexible and re-closable packaging solution for solid or viscous products in medium volume segment, where typically bottles, jerry cans or canisters are used.

The flexible packaging is an alternative to rigid buckets and canisters in volumes from 2 to 20 liters. The flexible structure allows to empty the packaging at highest rates.

The re-closable spout allows re-closure and the flexible structure allows the evacuation of air before closure and consequently lower the exposure of the content to oxygen.

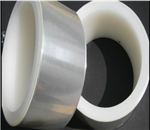

优秀轻质化产品奖:

颁发给Treofan/Borealis公司,其研发的新型电容薄膜的厚度仅为1.9微米。Treofan公司开发的这款电容器薄膜有着非常高的水平厚度均匀性,能量损耗很低,力学性非常好。Borealis公司研发了新型高纯度、等规聚丙烯钧聚无物,用以上述超薄薄膜的生产。Treofan和Borealis公司计划进一步提高这些薄膜的性能,降低其厚度并提高容积率、热塑性和电击穿电压水平。

This award recognises a company, which has created a product in any plastic technology that helped reduced weight for itself or for the end-product.

Treofan developed ultra thin capacitor films down to 1,9 um with a very high level of thickness homogeneity field stressability, low energy losses and very good mechanical characteristics.

Borealis AG developed a super pure, high isotactic polypropylene homopolymer with a novel polymer design that enables the production of these ultra-fins films.

Treofan and Borealis are planning to further improve those films enabling to additionally reduce thickness for increasing volume efficiency, thermal resistance and electrical break down voltage levels.

新型塑料制品表面创新奖:

颁发给Borealis聚合物公司,其与宝马公司合作研发生产的可染色汽车保险杠。针对在宝马这一非常大的应用市场中,新型Daphlen EE112AE级材料显示了Borealis公司对专业知识的掌握,以及整个产品和其配套应用的开发链,用以满足宝马公司油漆系统在保险杠外部塑料表面上的应用,并以之满足其德国式的苛刻设计和性能标准。据悉,使用此材料可减少生产周期并降低生产系统成本,这很有可能将在汽车保险杠这一细分行业中掀起一番新的革命。

This award recognises a company, which has created a product in any plastic technology with an innovative new surface for the application, improving any visual aspects or any tactile properties, or improving any functional surface aspects.

Developed in close partnership with BMW for use in its top vehicle range, the new grade Daplen™ EE112AE shows how Borealis and Borouge deliver expertise along the entire product and application development chain in order to facilitate primerless paint systems for exterior plastic applications which fulfil the most demanding design and performance criteria.

Primerless painting systems address the need for greater economy and sustainability in automotive exterior applications by reducing cycle time and system costs.

本文整理来源:塑商汇(sl168.com)和plasticseurope.org,仅供参考。